They are installed in the doorways of various premises, where their separation is obligatory under technology requirements or because of a difference of temperatures. They prevent air circulation – keep cool air in summer and heated-up air in winter. Such doors protect from dampness, drafts, noise and dust.

The doors are used in the shops to separate trading hall and subsidiary, where working personnel as well as goods are moving. They also may be installed in the special industrial premises (for example in meat processing and culinary shops of supermarkets, wash-houses etc.).

The doors have perfectly proved in the meat and fish processing enterprises where it is necessary to observe rules of hygiene, temperature modes, where personnel often moves. They can be used in another food enterprises as well (for example in bakeries, dairies).

Easy to pass by people and vehicles thanks to flexibility of the PVC material used in the door leafs, also thanks to the way the leafs are fastened in a doorframe on special spring mechanisms, providing free opening in both sides and returning the door to neutral position.

Swing doors made of flexible PVC are functional, safe, reliable, hygienic and simple in operation.

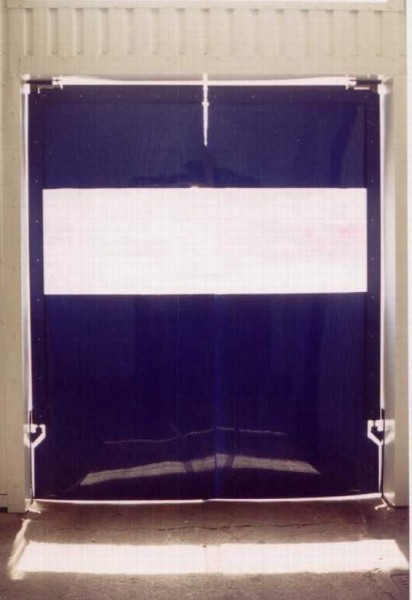

Door construction consists of a metal frame with leaf of flexible PVC material fixed. The frame by means of spring mechanisms of lateral type is fastened to special racks, which are installed in the doorway, or directly in the doorway with the help of torsion type spring mechanisms.

The welded metal frame can be made of stainless steel, or zincified metal, painted by powder or polymeric paint of various colours. The design of a frame allows easy changing of PVC leaf in case of necessity.

Flexible, plastified PVC material, 5,7,10mm thick, having high resistance on break and stretching is used to make the door leaf. The basic colours are transparent, grey and black. Combinations of these colours can be used in the leafs. Reliability and quality of welded seams allow using leafs consisting of two or three sections. The material is hygienic and easy to clean by means of water and soap.

PVC material features the following characteristics

| Characteristic | Method | Formula P.35 standard |

Formula P.45 low-temperature |

Unit of measurement |

| Density | DIN 53 479 |

1.22 | 1.18 | g/cm3 |

| Break point | DIN 53 372 | approx. – 35 | approx. – 45 | oC |

| Flexibility | DIN 51 948 | - 35 (no breach) | - 45 (no breach) | oC |

| Tension strain | DIN 53 455 | 300 | 420 | % |

| Tension strength | DIN 53 455 | 17 | 13 | MPa |

| Noise insulation | DIN 52 210 | -30 | -30 | dB |

| Light transmission | - | > 80 | > 80 | % |

Metal spring mechanisms (galvanized or corrosion-proof) of open lateral type or internal spring mechanisms of torsion type are used in the doors.

Lateral-type spring mechanisms are installed on the door leaf carrying frame laterally and allow to open it in both sides by 90 degrees, or if the door is installed at the doorway edge – by 180 degrees in one side and 90 degrees in the other.

|

|

|

| Neutral position of the leaf | 90o-open leaf | 180o-open leaf |

Internal spring mechanisms of torsion type are installed in the door leaf-carrying frame. Mechanisms of such type can be mounted directly in the doorway in its top part. In this case the door leaf is supported onto a special pad.

|

|

| 90o-open leaf | Pad-supported leaf |